AIMS:

- Future-orientedness of the Enterprise (actively assuming responsibility, targeted motivation of staff, improving corporate image, building up confidence and credibility in stakeholders, achieving better ratings for the enterprise, achieving environment awards and, Eco-Labeling, complying with new product guidelines)

- Innovative Products (finding innovative products through multidisciplinary work method, improving product quality, optimum adaptation of product to real customer needs, optimizing functionality of product, realizing new opportunities on the market through, environmentally sound high quality products, opening up new consumer segments)

- Improved Environmental Performance (avoiding potential damage to the environment and to corporate image, reduction of material and energy input, avoiding waste, emissions or toxicity, meeting consumers’ demand for environmentally friendly products, complying with environmental standards, complying with legal rules and regulations, ensuring workplace safety in the enterprise)

- Improved Cost Structure (favorable product characteristics through reduction of operational costs at use stage, lower overall production costs through saving on energy, auxiliary and operational materials in the enterprise, reduction of procurement costs by reducing material input in the product, avoiding or reducing costs for waste disposal

WHAT IT CONSISTS OF

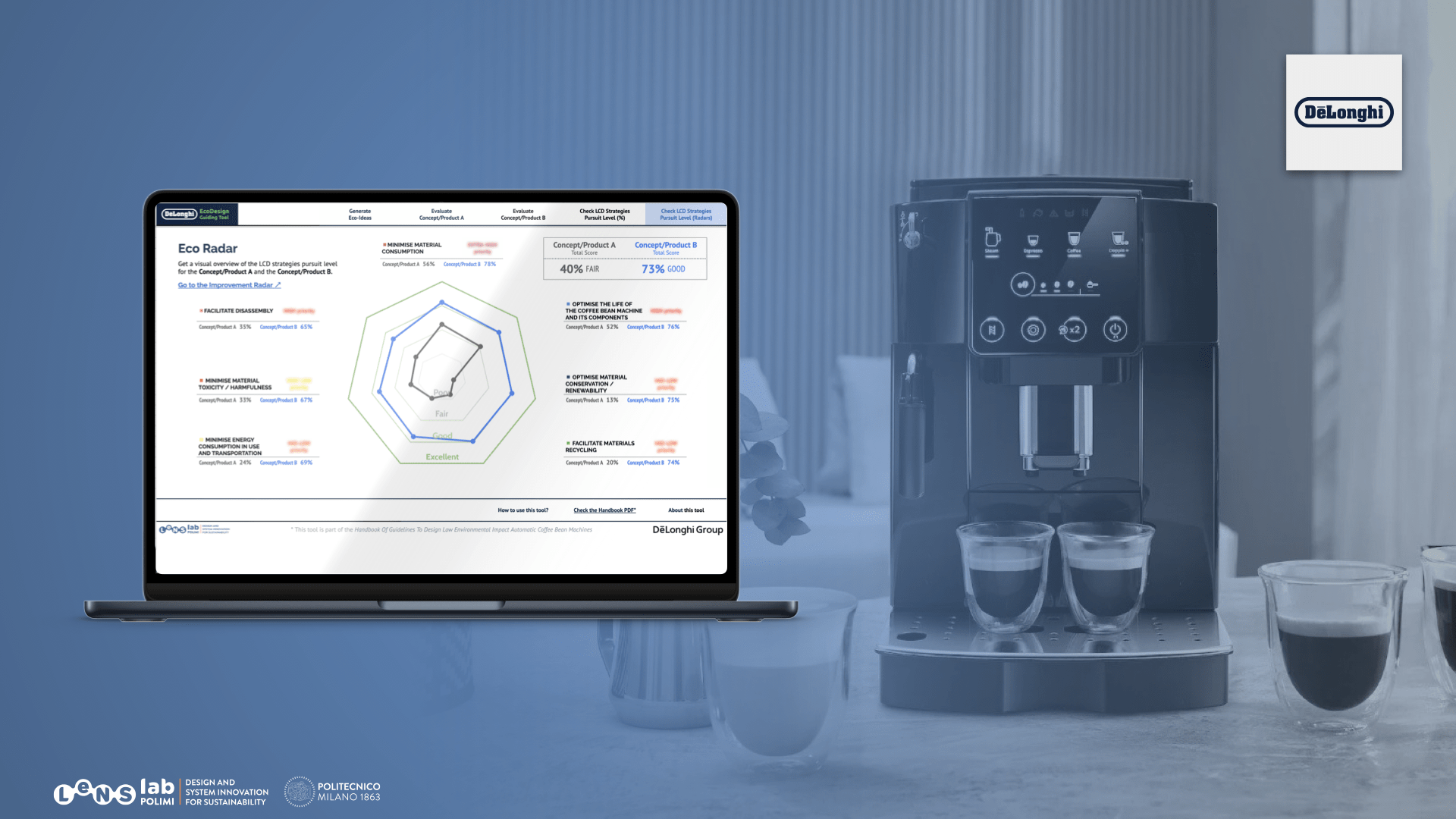

- ECODESIGN PILOT’s Assistant: A Support for finding product improvement strategies.

- ECODESIGN PILOT version 3: The implementation of ECODESIGN in practice is supported by the ECODESIGN PILOT.

HOW TO USE THE TOOL

- Starting with the ECODESIGN PILOT’s Assistant

- Completing the checklists below (Product name, product life time, functional unit), then click “goto next form”.

- Raw material:- Indicating the parts and components of product and its packaging. Then click “goto next form”.

- Manufacture: Indicating data referring to the manufacture of product. Again, getting support in assigning the different materials to the appropriate class of materials, click the help-symbol next to the “Class” heading.

- Distribution: filling in data concerning distribution of the product. Indicate average hauling distance and means of transportation used for the distribution of the product.

- Product use: This form addresses data concerning the stage of product use. Again, could click the help-symbol next to the “Class” heading.

- End of life: Indicating how the product will be disposed of at the end of its service life. The parts indicated here have been taken from the “Raw Material” form.

- Result: As a result, it will be able to identify the product type and appropriate ECODESIGN improvement strategies; a direct link gets you to the ECODESIGN PILOT checklists.

- Checklist for ECODESIGN analysis: what measures are appropriate for which product? Working through the checklists will result in a complete list of ECODESIGN measures particularly suited for your product.

- ECODESIGN Improvement: Starting with the PILOT along product development strategies enables to improve an existing product by means of appropriate ECODESIGN measures.

- Raw material intensive

RESULTS

Result in a complete list of ECODESIGN measures particularly suited for product.

TO VIEW AND DOWNLOAD THE TOOL : http://pilot.ecodesign.at/pilot/ONLINE/ENGLISH/MOTIV/INTRO.HTM

Product Processes and stages

- LCD strategies priorities definition (Product strategic brief/Design brief)

- Sustainable-focused ideas generation, selection and clustering (Product concept design)

- Design environmental sustainable concept (Product concept design)

- Most promising concept selection (Product concept design)